issue date:2016-3-31 15:35:44 visit frequency:5595

Metal coated mirrors are mirrors (optical reflectors) based on a thin metal coating, produced with an evaporation or sputtering technique. The metallic coating is placed on a substrate, which is often consisting of a glass, or possibly also of a metal. Common metal coatings consist of aluminum, silver or gold; less common are copper, chrome and various nickel/chrome alloys.

Often, the metal layer is covered with a thin layer or multiple layers of a dielectric material such as amorphous SiO2(silica) or Si3N4(silicon nitride),which protects the coating against oxidation(tarnish) and scratches. Such protected coatings are definitely more abrasion-resistant than uncoated ones, but still they tend to be more sensitive than dielectric mirrors. This implies that greater care is required for cleaning of meta-coated optics. Also, metallic mirrors are more or lenss sensitive to humidity and corrosive gases.

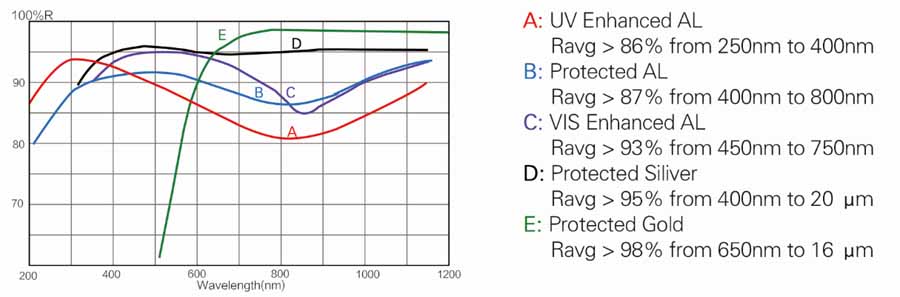

Multilayer protection coatings can also be used to enhance the reflectivity(see below):

|

Specifications |

||

|

Material |

N-BK7 ; UV Fused Silica;other optical glass |

|

|

Dimension Tolerance |

±0.0.5mm |

|

|

Thickness Tolerance |

||

|

Surface quality |

60/40 |

|

|

Flatness |

λ/4@633nm |

|

|

Parallelism |

<3' |

|

|

Clear Aperture |

>90% |

|

|

Bevel |

<0.25mm X 45° |

|

|

Coating |

One surface(S1): Polished and Metallic coating (Al, Ag, Au) The other surface: Fine ground Protected Aluminum :Ravg> 85%at400nm-800nm |

|

last:ZnSe

next:Corner Cube Prisms